Top Types of Cable Wire You Need to Know for Effective Wiring Solutions

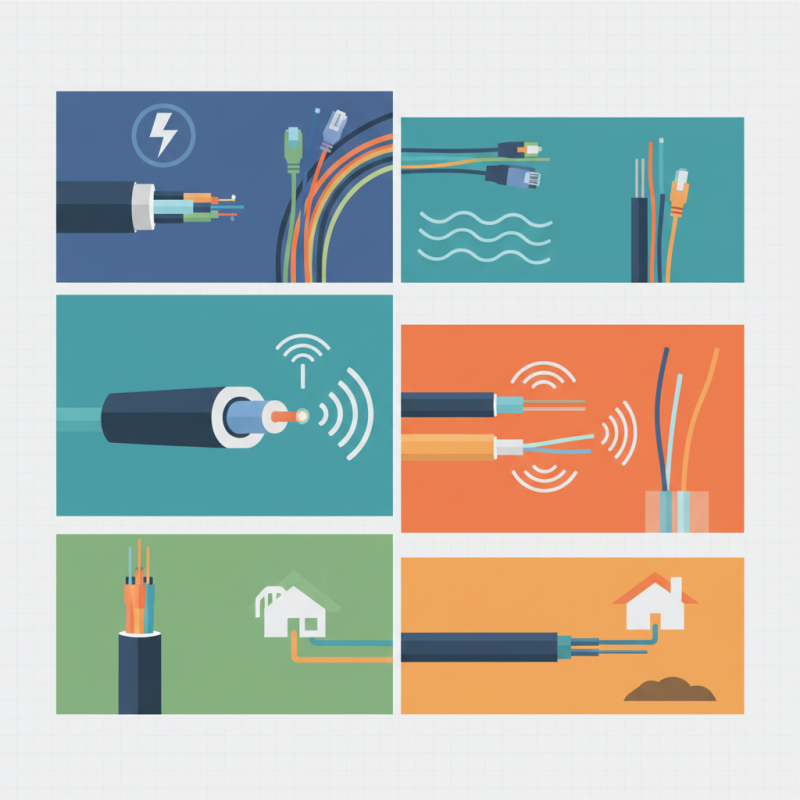

In today’s rapidly evolving technological landscape, understanding the various types of cable wire is essential for both professionals and DIY enthusiasts alike. The significance of selecting the right cable wire cannot be overstated, as it directly impacts the safety, efficiency, and durability of your wiring solutions. From electrical installations to telecommunications, the proper choice of cable wire ensures optimal performance and compliance with relevant standards.

This article aims to delve into the top types of cable wire that are crucial for effective wiring solutions. By exploring the characteristics and applications of each type, readers will gain valuable insights to help them make informed decisions for their specific needs. Whether you are dealing with residential projects or commercial installations, comprehending the differences among various cable wire types will equip you with the knowledge needed to tackle any wiring challenge with confidence and precision.

The Importance of Choosing the Right Cable Wire for Wiring Solutions

Choosing the right cable wire is crucial for ensuring the efficiency and safety of any wiring solution.

The type of cable wire you select affects everything from the performance of your electrical systems

to the longevity of the installation. Different applications require specific types of cables,

so understanding their unique characteristics is vital. For instance, certain wires are better

suited for high voltage or high current loads, while others may be more appropriate for

data transmission.

Tips for Choosing the Right Cable Wire:

- Consider the Application: Identify the purpose of the wiring. For indoor use, standard PVC cables might suffice, but outdoor installations may require weather-resistant materials.

- Check Ampacity Ratings: Before purchasing cable wire, ensure it can handle the electrical load. Use charts that provide ampacity ratings according to wire gauge and insulation type.

Additionally, pay attention to installation conditions. Factors such as temperature, exposure to moisture, and physical wear can impact the performance of the cable. Selecting wires with appropriate insulation and protective measures can provide the durability needed for long-term use. By carefully considering these aspects, you can create effective and safe wiring solutions tailored to your specific needs.

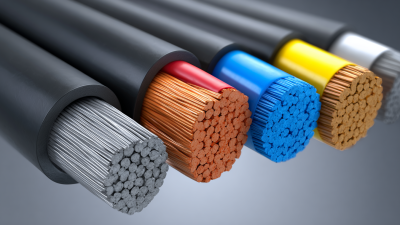

Types of Copper and Aluminum Wires: Benefits and Applications

When it comes to wiring solutions, understanding the types of copper and aluminum wires is essential for optimal performance in various applications. Copper wire is widely preferred for its excellent conductivity, which allows for efficient transmission of electricity. It is highly durable, resistant to corrosion, and can handle high temperatures, making it a popular choice for electrical systems in residential and commercial buildings. Its flexibility also allows for easier installation, making it a favorite among electricians.

On the other hand, aluminum wire, while slightly less conductive than copper, offers several advantages that make it a viable alternative. Aluminum is lighter and generally more cost-effective, making it a suitable option for overhead power lines and larger electrical projects where weight is a concern. However, it is important to use appropriate connectors and installation techniques to prevent issues such as oxidation and expansion. Understanding the unique benefits and applications of these wire types allows professionals to make informed decisions based on the specific requirements of each project, ultimately leading to more effective and reliable wiring solutions.

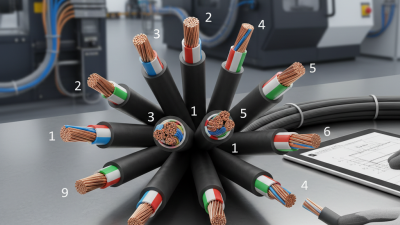

Top Types of Cable Wire You Need to Know for Effective Wiring Solutions

| Type of Wire | Material | Benefits | Applications |

|---|---|---|---|

| THHN Wire | Copper | High heat resistance, low moisture absorption | Residential and commercial wiring |

| XHHW Wire | Copper | Moisture, chemicals, and abrasion resistant | Service entrance and outdoor applications |

| NM Cable | Copper | Easy to work with, flexible | Indoor residential wiring |

| MC Cable | Copper/Aluminum | Durable, fire-resistant | Commercial buildings and installations |

| Aluminum Wire | Aluminum | Lightweight, cost-effective | Power distribution, feeders |

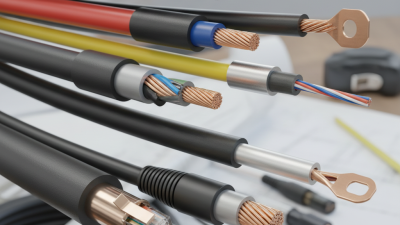

Understanding Insulation Types in Cable Wiring: A Comprehensive Guide

When it comes to cable wiring, understanding the various types of insulation is crucial for ensuring safety and efficiency. Insulation materials serve as the protective layer around the conductive wires, preventing electrical leaks and safeguarding against environmental factors. Common insulation types include PVC (polyvinyl chloride), which is widely used for its cost-effectiveness and versatile properties, and XLPE (cross-linked polyethylene) that offers superior thermal resistance and durability. These materials provide insulation against moisture, heat, and mechanical stress, making them suitable for different applications in residential and industrial settings.

Moreover, the choice of insulation can significantly impact the performance and longevity of the wiring solutions. For instance, Teflon insulation is known for its excellent resistance to high temperatures and chemicals, making it ideal for applications in harsh environments. Understanding the thermal ratings and voltage capacities of insulation materials helps in selecting the right type for specific wiring projects. By making informed decisions about insulation types, electricians and DIY enthusiasts can ensure that their wiring systems function reliably and safely over time, adhering to industry standards and enhancing overall performance.

Key Specifications: Gauge, Voltage, and Ampacity Explained

When it comes to effective wiring solutions, understanding key specifications like gauge, voltage, and ampacity is essential. The gauge of a wire refers to its diameter, which directly influences its resistance and current-carrying capacity. A lower gauge number indicates a thicker wire, which is capable of handling higher currents. For instance, a 10-gauge wire can manage significantly more ampacity compared to a 14-gauge wire. Choosing the right gauge is crucial for both safety and efficiency, as undersized wires can lead to overheating and potential fire hazards.

Voltage is another critical factor in wiring specifications. It denotes the electrical potential difference capable of driving current through a circuit. Each wiring application has a specific voltage requirement, and exceeding this can not only damage the insulation but also compromise the entire electrical system. It's vital to match the wire's voltage rating with the intended application, ensuring the wire can withstand the electrical pressure without degradation over time.

Ampacity, the maximum amount of electric current a conductor or device can carry before sustaining immediate or progressive deterioration, is closely related to both gauge and voltage. Understanding ampacity ratings helps in selecting the appropriate wire for particular applications, especially in residential and commercial installations where circuits can draw variable amounts of current. Adequate knowledge of these three elements—gauge, voltage, and ampacity—allows for safer, more effective wiring solutions tailored to specific needs.

Common Failures and Solutions in Cable Wiring: Best Practices to Follow

Common failures in cable wiring often stem from improper installation techniques, environmental factors, or inadequate materials. One prevalent issue is the insulation failure, which can result from exposure to extreme temperatures or physical abrasion. This can lead to short circuits, electrical fires, or equipment damage. To mitigate these risks, it’s critical to use cables with appropriate insulation ratings for the intended environment and to employ protective conduits where necessary. Regular inspection and maintenance of cable systems can also help identify potential problems before they escalate.

Another common failure is inadequate grounding or bonding, which plays a vital role in electrical safety. Poor grounding can increase the likelihood of electrical shock and equipment malfunction. Best practices include ensuring that all wiring is correctly grounded and that connections are tight and corrosion-free. Implementing regular testing of grounding systems can help maintain system integrity. Additionally, following standardized wiring diagrams and adhering to local electrical codes can significantly reduce installation errors and enhance the overall reliability of cable wiring solutions.

Top Types of Cable Wire for Effective Wiring Solutions

This chart illustrates the most common types of cable wire used in wiring solutions, highlighting potential common failures and their frequency. Understanding these can help in choosing the right cable wire for various applications while being aware of issues that may arise.

Related Posts

-

Exploring the Advantages of 4 Core Cable in Modern Electrical Installations and Its Impact on Efficiency

-

How to Choose the Right Welding Cable for Your Projects in 2025

-

Top 10 Control Cable Types for Optimal Performance in Industrial Applications

-

Top 10 Uses of Thermocouple Wire in Industrial Applications

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

-

2025 Guide to Choosing the Right Wire and Cable for Your Projects