How to Select the Right MC Cable for Your Electrical Projects

Choosing the right MC cable for your electrical projects can significantly influence the overall safety and efficiency of your installations. As industry expert John Doe, a seasoned electrical engineer with over 20 years of experience, aptly stated, “Selecting the appropriate MC cable is essential for ensuring durability and performance in various environments.” This highlights the importance of understanding the different types of MC cables available and their specific applications.

When embarking on an electrical project, the complexity of the selection process can be daunting, especially for those unfamiliar with the specifications and standards. MC cables, or metal-clad cables, are favored for their resilience and versatility, making them suitable for a wide range of uses, from residential wiring to large commercial installations. It is crucial to consider factors such as the environment, load requirements, and regulatory standards to choose the perfect MC cable that meets the demands of the job.

Ultimately, being well-informed about the characteristics and advantages of MC cables not only enhances the efficacy of your projects but also provides peace of mind regarding safety and compliance. With the right knowledge and guidance, you can navigate the selection process confidently, ensuring that your electrical installations are up to code and built to last.

Understanding MC Cable and Its Applications

MC cable, or Metal-Clad cable, is a type of electrical cable that is widely used in various applications due to its versatile nature and robust construction. This cable consists of insulated conductors encased in a metallic sheath, which provides enhanced protection against environmental factors and mechanical damage. MC cable is often utilized in commercial and industrial settings, particularly where flexibility and reliability are paramount. Its ability to withstand harsh conditions makes it ideal for use in both indoor and outdoor electrical installations.

In addition to its durability, MC cable offers significant advantages in terms of fire resistance and safety. The metallic jacket serves not only as a barrier against physical threats but also as a grounding conductor, which improves the overall safety of the electrical system. This makes MC cable a preferred choice for applications in hazardous locations, as well as in areas requiring strict adherence to safety codes and standards. Understanding the specific applications of MC cable is crucial for selecting the right type for your electrical projects, ensuring optimal performance and compliance with regulatory requirements.

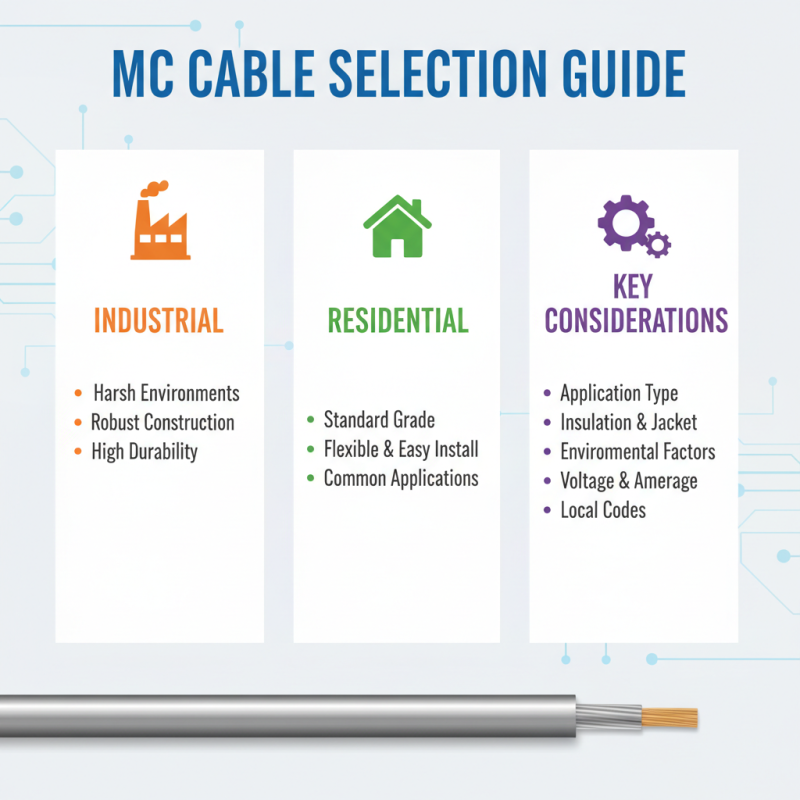

Factors to Consider When Choosing MC Cable

When selecting the right MC (Metal Clad) cable for electrical projects, several key factors should be considered. First, evaluate the application of the cable. Different projects may require various types of insulation and durability levels. For example, industrial settings may demand a more robust construction to withstand harsh environmental conditions, while residential projects might require standard-grade MC cable.

Another crucial consideration is the cable's size and ampacity, which refers to the amount of current the cable can safely carry. It’s important to consult local electrical codes to ensure compliance with regulations and to select an appropriate cable size that will handle the anticipated electrical load without overheating.

**Tips:** Always check the specific environmental factors, such as exposure to moisture or chemicals, that could affect cable performance. Additionally, consider whether you need direct burial or if the cable will be exposed to physical damage, as this will influence your choice. Lastly, think about the ease of installation and whether you require additional features like flexibility or enhanced protection.

Different Types of MC Cables and Their Features

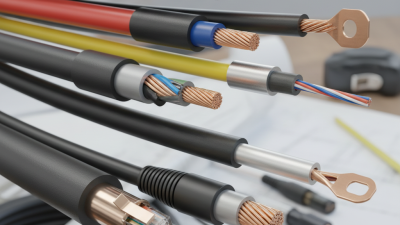

When selecting the right MC (Metal Clad) cable for electrical projects, understanding the different types available is essential. MC cables generally consist of multiple conductors encased in a flexible metal sheath, providing durability and protection. The most common types include bare, insulated, and armored MC cables. Bare MC cables are typically used for indoor applications where further insulation isn't necessary, while insulated cables feature individual conductors with a plastic or rubber coating, making them suitable for environments that require additional protection against moisture and abrasion.

Armored MC cables, on the other hand, are designed for heavy-duty applications and can withstand harsh conditions. They are usually employed in industrial settings or outdoor installations, where exposure to elements is a concern. Additionally, some MC cables come with additional features such as moisture-resistant coatings or fire-rated materials, which enhance their usability in specific environments. Evaluating the project requirements alongside these varying capabilities ensures the selection of the most appropriate cable type for safe and efficient electrical installations.

Evaluating Environmental and Installation Requirements

When selecting the appropriate MC (metal-clad) cable for electrical projects, evaluating environmental and installation requirements is crucial. One of the first considerations should be the physical environment where the cable will be installed. Factors such as moisture, temperature extremes, and exposure to chemicals can significantly impact the performance and longevity of the cable. For instance, if the environment is prone to high humidity or direct contact with water, opting for MC cables with additional water-resistant features will be beneficial. Similarly, if the installation is in a high-temperature setting, choosing cables with higher temperature ratings can prevent insulation damage and ensure safety.

Additionally, the installation method plays a vital role in the selection process. Cables that will be run in conduit, for example, may not require the same level of durability as those exposed to outdoor elements. Consideration should also be given to the cable's weight and flexibility, especially in applications requiring frequent movement or bending. The degree of ruggedness needed will depend on whether the installation is in a residential or industrial setting. By assessing both environmental factors and installation specifics, one can make a more informed decision on the right MC cable that meets both safety and operational efficiency requirements.

How to Select the Right MC Cable for Your Electrical Projects - Evaluating Environmental and Installation Requirements

| Cable Type | Conductor Material | Insulation Type | Ampacity Rating | Temperature Rating | Suitable Environments |

|---|---|---|---|---|---|

| MC-HL (Metal Clad High-Low) | Copper | PVC | 90 A | 90°C | Indoor/Outdoor, Wet Locations |

| MC-G (Grounded) | Aluminum | XLPE | 105 A | 90°C | Indoor, Dry Locations |

| MC-XL (Xtreme) | Copper | Thermoplastic | 75 A | 80°C | Indoor, High Flexibility |

| MC-TE (Temperature Resistant) | Copper | RTD Polyethylene | 120 A | 105°C | Indoor, High Temperature Environments |

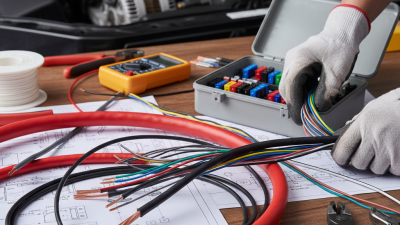

Best Practices for MC Cable Installation and Maintenance

When it comes to the installation and maintenance of MC (Metal Clad) cables, adhering to best practices is crucial for ensuring safety and reliability in electrical projects. A significant factor to consider is the environmental conditions where the cables will be installed. According to industry reports, the failure rate of electrical systems can increase by up to 25% when cables are not properly rated for their intended environment, such as high-temperature areas or moist conditions. Therefore, selecting the right insulation and shielding for the specific installation site can drastically affect the longevity and performance of MC cables.

During installation, following the National Electrical Code (NEC) guidelines is essential. Proper bending radius, avoiding sharp kinks, and ensuring that cables are not overly compressed can prevent damage and enhance the overall durability of the installed system. A report from the Electrical Safety Foundation International (ESFI) indicates that improper installation practices account for nearly 30% of electrical accidents. Thus, training personnel in best practices for handling and installing MC cables not only promotes safety but also complies with industry standards, ultimately resulting in a more robust electrical infrastructure.

Regular maintenance checks, including visual inspections for signs of wear and tear and ensuring that connectors remain tight, are equally important to maintain system integrity throughout the lifespan of the cable.

Related Posts

-

2025 Guide to Choosing the Right Wire and Cable for Your Projects

-

Top Wire Connectors: Choosing the Best Types for Your Projects

-

2025 Top 5 Industrial Electric Wire and Cable Solutions for Every Business Need

-

Maximizing Safety and Efficiency: The Essential Guide to Choosing Electrical Wire Connectors in 2023

-

Top 10 Benefits of Using 2 Wire Systems for Efficient Connectivity

-

10 Essential Tips for Choosing the Right Automotive Wire for Your Needs