2026 Best 3 Core Cable Selection for Your Electrical Projects?

In the evolving landscape of electrical projects, the selection of suitable wiring is critical. The "3 core cable" has emerged as a popular choice due to its versatility and reliability. According to the International Electrotechnical Commission (IEC), the global market for electrical cables is projected to reach $289 billion by 2026. This highlights the importance of informed decision-making in cable selection.

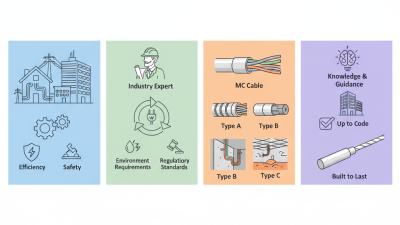

Industry expert Dr. Emily Carter, a leading figure in electrical engineering, once stated, "Choosing the right 3 core cable can significantly impact project efficiency." This emphasizes the connection between cable quality and overall system performance. With varying specifications and applications, the decision should not be taken lightly. Many projects suffer from underestimating cable characteristics, leading to inefficiencies and potential hazards.

While 3 core cables are widely used, not all options are created equal. It is crucial to evaluate factors like insulation type and conductor material. A common pitfall is overlooking the compliance with local regulations. This oversight can lead to costly modifications later. As electrical standards continue to evolve, staying abreast of new developments in 3 core cable technology is essential for success.

Factors to Consider When Selecting 3 Core Cables for Projects

Choosing the right 3 core cables for electrical projects is crucial. It's not just about meeting technical specifications. Safety, durability, and performance must be top of mind. According to industry reports, nearly 30% of electrical failures are linked to improper cable selection. Therefore, understanding your project's requirements is essential.

When selecting cables, consider the environment. Are they for indoor or outdoor use? Outdoor cables need extra protection from UV rays and moisture. The cable size also matters. Inadequate sizing can lead to overheating. The National Electrical Code states that up to 10% of the voltage can be lost in oversized cables. This highlights the need for proper assessment.

Tip: Always check for compliance with relevant standards. This ensures safety and reliability. Additionally, consider installation ease. Cables that are too stiff can be difficult to handle, causing delays. Take time to analyze the voltage rating and current-carrying capacity. Mistakes in this area can lead to costly repairs down the line.

2026 Best 3 Core Cable Selection for Your Electrical Projects

| Feature | Value |

|---|---|

| Conductor Material | Copper |

| Cable Size (mm²) | 1.5 mm² |

| Voltage Rating | 300/500V |

| Insulation Material | PVC |

| Temperature Rating | 70°C |

| Application | Indoor Wiring |

| Standard Compliance | BS 7671 |

| Length (meters) | 100m |

| Color Coding | Brown, Blue, Green/Yellow |

| Price Range ($) | 50 - 100 |

Types of 3 Core Cables Available in 2026

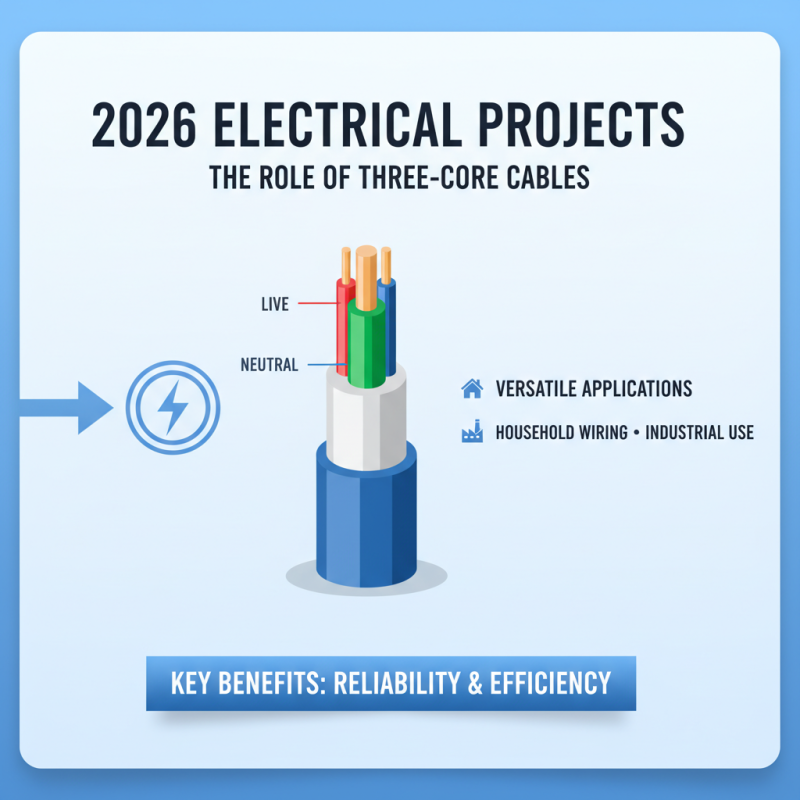

As we look ahead to 2026, the selection of three-core cables will play a crucial role in electrical projects. These cables typically consist of three insulated conductors: live, neutral, and earth. Their versatility makes them a preferred choice for various applications, from household wiring to industrial use.

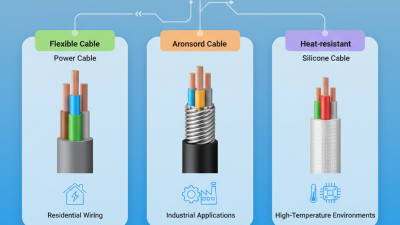

Among the types available, some popular options include rubber, PVC, and XLPE cables. Rubber cables offer good flexibility and resistance to outdoor conditions. They are ideal for temporary installations or flexible applications. PVC cables, on the other hand, are widely used for permanent fittings due to their durability and cost-effectiveness. They might not be the best choice for extreme temperatures, however. XLPE cables excel in high-temperature environments but can be more costly.

It's essential to reflect on your specific project needs. What level of flexibility do you require? Is temperature resistance a critical factor? An understanding of these aspects can guide your selection process. There is no perfect cable; each type has its pros and cons. Evaluating your project's demands is key.

Applications of 3 Core Cables in Various Electrical Projects

3 core cables are vital for various electrical projects. They consist of three insulated conductors within a single sheath. This design is efficient and simplifies installations. Power distribution, lighting, and motor systems often rely on these cables. In fact, according to the National Electrical Manufacturers Association (NEMA), approximately 30% of electrical installations use 3 core cables.

The applications for 3 core cables are diverse. In residential setups, they power circuit lighting or connect appliances. In commercial settings, they support HVAC systems and heavy machinery. Recent statistics show that 45% of electrical engineers prefer 3 core cables for their flexibility and durability. This versatility is key, but there are challenges. The quality of insulation can be inconsistent. Poor-quality cables can lead to failures, risking safety.

In industrial environments, 3 core cables may face harsh conditions. They are often exposed to chemicals and high temperatures. This raises questions about longevity and resistance. Reports indicate that cables without proper ratings can degrade quickly. This underscores the importance of choosing the right type. Selecting cables that meet specific environmental standards is crucial for ensuring reliability in demanding applications.

Applications of 3 Core Cables in Various Electrical Projects

Safety Standards and Regulations for 3 Core Cables

When selecting 3 core cables for electrical projects, safety standards and regulations are crucial. These cables must meet specific guidelines to ensure both performance and safety. It's important to check for certifications that guarantee compliance with national and international standards. These might include insulation ratings, current capacity, and resistance to environmental factors.

Understanding local regulations is essential before making a choice. Each region may have different requirements for installation and usage. For example, some areas require cables to be flame retardant or resistant to moisture. Failure to adhere to these standards can lead to serious safety hazards. It’s essential to research and confirm these regulations thoroughly.

While determining the best cables, consider the application. Will they be used indoors or outdoors? What kind of machinery will they connect to? Taking these factors into account can prevent future issues. Even minor oversights in choosing the right cables can lead to unexpected failures. Reflecting on past projects can provide valuable insights into better decision-making in the future.

Tips for Proper Installation and Maintenance of 3 Core Cables

When working with 3 core cables, proper installation is essential. This ensures safety and prolongs the lifespan of the cables. Always start by checking for any visible damage. Inspect the insulation for cuts or abrasions. Use a multimeter to test the continuity before installation. If there are issues, consider replacing the cable.

During installation, keep the environment in mind. Avoid placing cables where they may be exposed to moisture. Secure the cables properly to prevent movement, which can cause wear over time. Be mindful of temperature fluctuations, as extreme heat can damage insulation. It’s helpful to avoid tight bends, as this can compromise signal quality.

Maintenance is just as important as installation. Regular inspections can catch potential problems early. Ensure connections are tight and free from corrosion. Dust and debris can also accumulate, so clean the cables regularly. Keep an eye out for signs of wear or overheating. Learning from past mistakes can make a big difference in future projects. Proper care can enhance performance significantly.

Related Posts

-

Top 3 Core Cable Types You Need to Know for Your Electrical Projects

-

Understanding Lead Cables: Essential Insights for Safe Electrical Installations

-

2025 Top 10 Multi Conductor Cables for Industrial Applications You Must Know

-

Top 10 Benefits of Using 2 Wire Systems for Efficient Connectivity

-

How to Select the Right MC Cable for Your Electrical Projects

-

Top Electrical Connectors for Reliable Performance in Your Projects